Specific benches for your needs

To develop a specific bench adapted to your needs, we mobilize our skills in mechatronics, combining mechanics, electronics and software. Our expertise extends to crucial areas such as structural calculation, vibration modes and simulation, forming the basis of our technical approach.

The Emitech Group's experience feedback in motorization, electrification and environmental constraints offers you a unique advantage in the automotive sector. We have specific expertise in thermal, hybrid and electric powertrains, as well as in innovative energies such as hydrogen (H2), ammonia (NH3) and e-fuels.

Our know-how also extends to fields such as hydraulics, regulation, advanced mechanics, electronics and electrical machines.

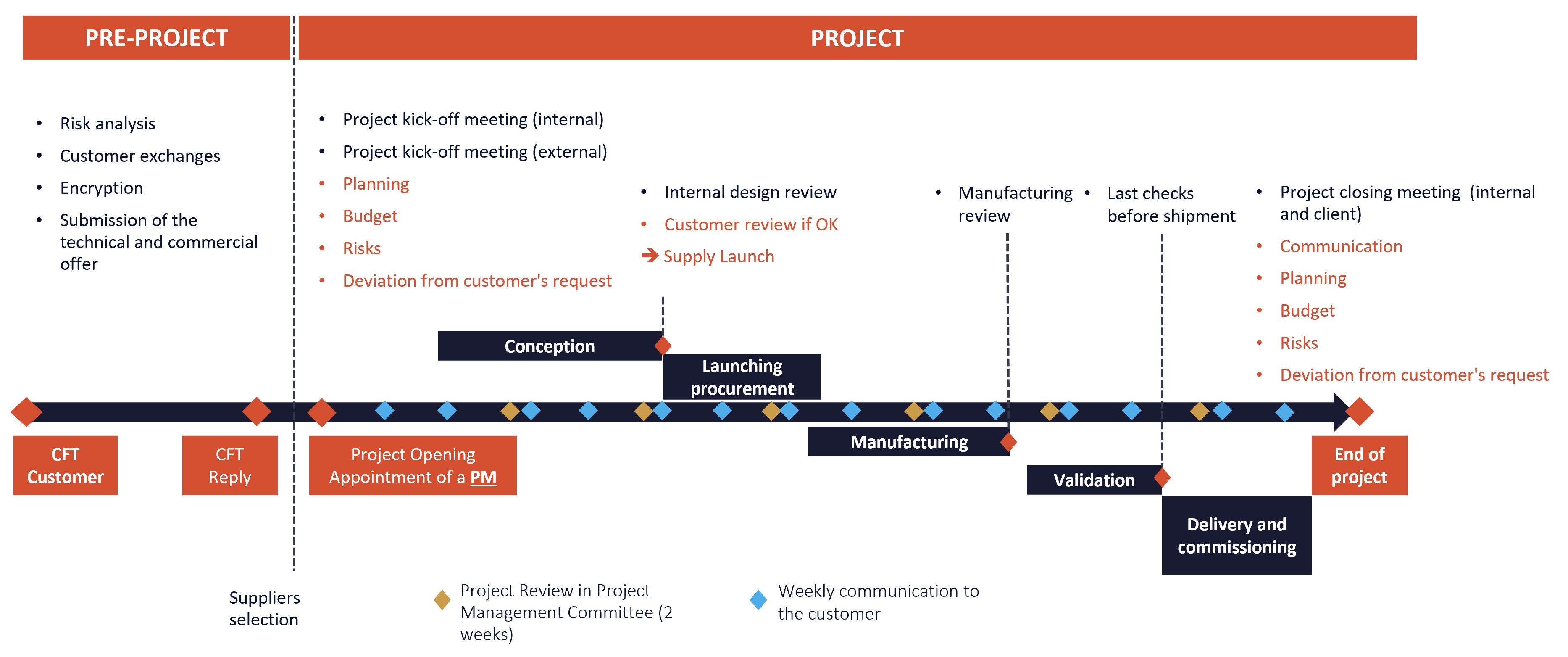

Throughout the process of creating your test bench, our project managers work closely with you.

Architect and integrator of complex solutions

Upstream, analysis of your specification or call for tender

Risk analysis

- Availability of required skills

- Schedule of workload vs. expected delivery time

- Are specifications finalized?

Technical exchanges

- Listing of customer requirements

- Open point files with customer

- Visit to customer's premises customer's premises

- Synoptic proposal

- Layout diagram

- Supplier exchanges

- Brand/reference proposal for predominant hardware on project

Our pre-study includes a risk analysis, technical discussions with you and our suppliers, the establishment of a costing and the submission of our technical and financial offer.

Our aim is to secure the entire project for a balanced relationship of trust covering the quality of deliverables, deadlines and costs.

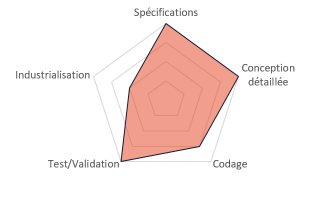

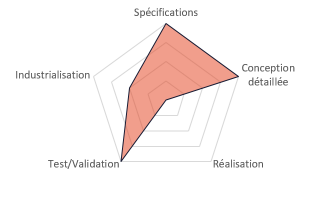

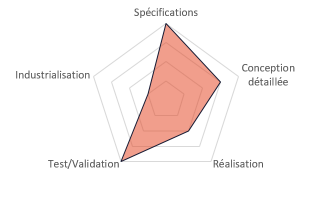

Project-based management for continuous quality control, deadlines and costs

As soon as you accept our offer, you will be assigned a dedicated project manager who will coordinate all the parties involved.

Weekly communication is set up to review progress and address points related to design, human machine interface (HMI), planning, procurement deadlines, lists of actions to be carried out in the coming weeks.

A fortnightly steering committee produces a progress summary, keeps the project dashboard and project risk analysis up to date.

Support, maintenance and after-sales service

We stand by our customers and provide long-term support for our benches and installations.

We support you throughout the entire lifecycle of your products, providing maintenance but also enabling you to upgrade or retrofit them.

Our maintenance services can be both preventive and curative.

Preventive maintenance

You retain the characteristics and performance of your test equipment

- Maintenance of original technical specifications

- Advice for optimum use

- Free telephone support

Curative maintenance

You remedy breakdowns, failures and malfunctions of your means

- Pre-diagnosis of the breakdown

- Intervention of an expert technician within the contractual timeframe

- Permanent stock of critical parts according to the contract

We offer a level of maintenance adapted to your use. The frequency and duration of our interventions are defined beforehand and commit us to the availability rate of your equipment. We draw up a maintenance register and issue you with a verification report referring to the requirements of ISO 17025

Focus on our bench design skills

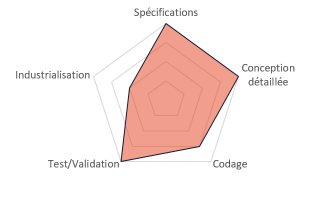

Activities

- Control command

- System and control law modeling

- Coding - Autocode

- Automation

- Testing and validation

- Electronic/electrical architecture

Domains / Systems

- On-board calculator

- Test bench

- Rail opening systems

- Marine propulsion systems

- Radar systems

Profiles

- Labview Design Engineer

- Modeling Engineer

- Automation Specialist

- Embedded Developer

- Software Architect

- Validation engineer

Software: LabView, Simulink, Stateflow, TestStand

Languages: C, C++, Python, Matlab

Standards: ISO 26262, EN 50128

Activities

- Map design

- Schematic - Routing follow-up

- Map testing and validation

- System testing, HIL testing

- CEM

Domains / Systems

- Signal, image processing

- Power electronics

- Analog, digital electronics

- LV/HV electrical

Profiles

- Electronics Engineer

- Electrical Engineering Engineer

- Validation Engineer

- Electrical/Electronics Validation Technician

Software:

- Altium Designer

- Orcad

- Pspice

- Dspace

- See Electrical

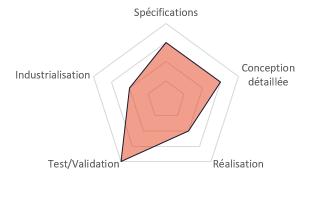

Activities

- Specification

- CAD - drawing

- Calculation - modeling

- Vibratory sizing

- Mechanical, climatic, environmental testing

Domains / Systems

- Test benches

- Marine propulsion systems

- Flight controls

- Cockpit

- Battery

Profiles

- Design Engineer/Technician

- Calculations Engineer

- Validation Engineer

- Mechanical Engineer

- Test Technician

Software:

- CATIA

- Creo

- Ansys

- SolidWorks

Activities

- Modeling

- Sizing

- Yield determination

- Testing and validation

- Calibration

Domains/Systems

- Combustion engine/electric/hybrid

- Combustion

- Thermal

Profiles

- Energy Engineer

- Propulsion Engineer

- Thermal Engineer

- Test Engineer

- Validation Engineer

- Tune-up Engineer/Technician

Software :

- Simulink

- Stateflow

- TestStand

- AMESim

- GTSuite

- Converge

- INCA

Activities

- Specification

- Sizing

- Modeling Simulation

- Control command

- Testing

Domains / Systems

- GMP Hybrid and Electric

- Marine propulsion systems

- Battery

- Landing gear

- Electric machinery

Profiles

- Power Electronics Engineer

- Automation Engineer

- Test Engineer and Technicians

Software:

- Matlab

- Simulink

- Stateflow

- Dspace

Activities

- Laboratory testing

- On-site measurements (acquisition, analysis, diagnostics)

- Expertise in technological choices, design review, compliance

- Documentary editing (EMCCP, QTP, QTR, Similarity reports)

- Project follow-up (assistance, coordination, . ...)

- Qualification follow-up (qualification plan, test follow-up and management...)

- Approval follow-up (normative and regulatory watch, marking validation, ...)

- Digital simulation

Domains / Systems

- Product development

- Qualification, product certification

- Homologation worldwide

- Waves and health

Profiles

- Test engineers and technicians

- Test manager

- Project manager / Coordinator

- Qualification / Certification engineer

- Measurement engineer and technician

Environments:Safety, Radio frequency, EMC / Electrical / Lightning, Vibration / Shock / Jolt, Climatic / Physico-chemical, Hydraulic, Acoustics, Fire

Languages: BatEMC, Accys, Pulsar, Concerto, MDA, Diadem

Standards: ISO 9001, ISO 17025

Transformation of existing benches, retrofits...

Our teams are able to upgrade the benches present in your facilities.

Our retex is particularly important for work carried out on our own installations to operate our traditional ICE engine test beds with synthetic fuels (e-fuel) or even to modify them more thoroughly for operation with the addition of H2 and NH3.

Examples of elements to integrate for retrofitting an ICE e-fuel dyno

- Adjustments in the fuel supply system and injectors for e-fuel devices

- Modifications in emissions measurement systems to accurately assess NOx, CO2, particulates, etc.

- Adjustment of combustion parameters such as air/fuel ratio, temperature and pressure, adapted to e-fuel characteristics.

Example of the transformation of an ICE bench into an ICE H2/NH3

Catalog and customizable solutions

EMCEM bench

Realisation of a test facility dedicated to the characterisation of an electric motor in electromagnetic compatibility (ElectroMagnetic Characterisation of Electric Motor)

- High dynamic bench (20,000 rpm / Cmax: 510 Nm / Pmax: 280kW)

- Acquisition bay (frequency from 1 to 100Hz) with multiple power supplies and inputs

- Power supply, battery simulator, loads. ..

- Water and oil thermal regulation

- Availability of CISPR25-compliant shielded HV RSILs up to 800Adc

- Steering software solution: EMC Means + Pulsar + Pulsar Vibe

- The PLUS: installation of a rotating engine test bench protected against any interference and installed in a dedicated " automotive " CISPR25-compliant Faraday cage

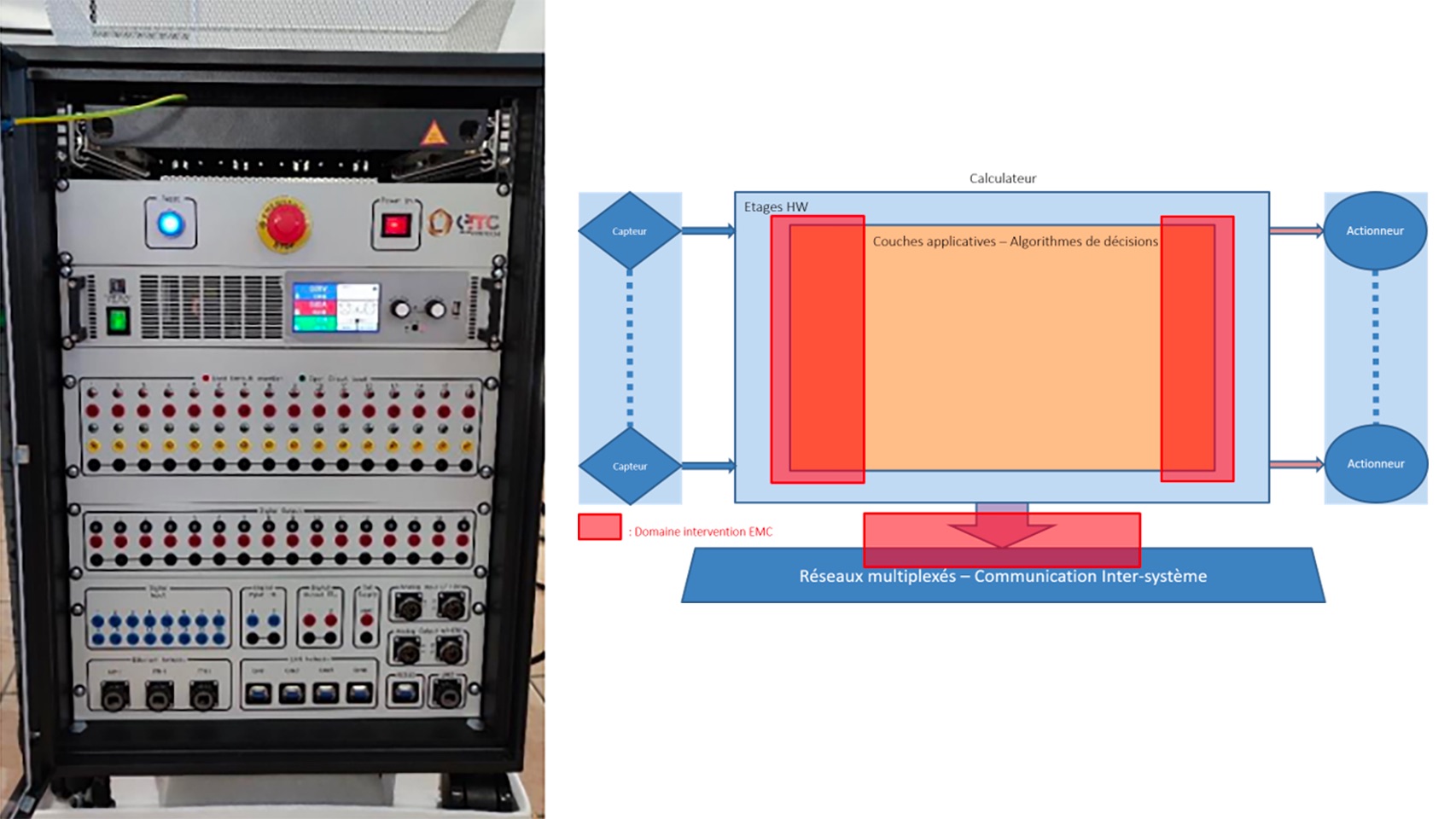

PULSAR bay

A ready-to-use bay that enables open-loop validation of ECU I/O

-

1 controllable power supply to simulate battery voltage (Vbat).

-

16 analog inputs (-10v / +10v) and 16 digital inputs (Vbat) to read the status of ECU commands.

-

16 analog outputs (-10v / +10v), 8 PWM outputs (Vbat) and 8 digital outputs (Vbat) to simulate sensors.

-

2 TTL outputs to simulate engine and camshaft speed.

-

16 load channels with fault insertion.

-

4 CAN ports (optionally LIN-modifiable).

-

1 quick connector for ECU interfaces

EPAC bench

Conducting electrical safety and EMC tests in accordance with the requirements of standard EN15194 as part of the CE marking of an electrically power assisted cycles (EPAC).

- Functionality for 20- to 28-inch bikes

- Front and rear wheel synchronization via belt mechanism

- Three independent motorizations and torque measurements (front wheel / rear wheel rear / crankset)

- Adjustable load from 0 to 600W

- Speed control from 0 to 100rpm

- Static torque control from 0 to 90Nm and dynamic torque

- Dedicated software solution

- The PLUS : the EPAC bench is designed not to influence measurements in electromagnetic emission and not to be disturbed in immunity